Menu

-

MenuBack

- Category

- Home

-

On Sale

-

-

All sale >

-

-

-

-

About Company

-

-

Wiecej na proxima-adhesives.pl

-

-

-

Access map

-

-

YOU MUST BE LOGGED IN TO SEE PRODUCT PRICES AND PLACE AN ORDER.

Filter By

Brand

Brand

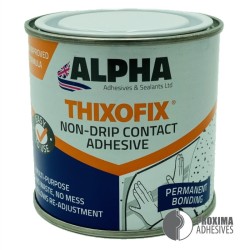

solvent and dispersion adhesives

One- and sometimes two-component adhesives based on neoprene rubbers, SBR, nitrile, polyurethane, natural rubber.

Used for a wide range of materials, most often flexible.

Examples of applications: gluing conveyor belts, pontoons, life rafts, life jackets, diving suits, carpets, sealing materials, natural and artificial leather, rubber.

Not all products are included on the store's website. In the absence of the desired product, please ask the store staff about availability.

There are 17 products.

Showing 1-17 of 17 item(s)

Active filters